Reddit mentions: The best household poly & varnishes

We found 221 Reddit comments discussing the best household poly & varnishes. We ran sentiment analysis on each of these comments to determine how redditors feel about different products. We found 86 products and ranked them based on the amount of positive reactions they received. Here are the top 20.

1. Pour-On Epoxy Finish Is Equal To 60 Coats Of Varnish And Provides A Gorgeous High Gloss Appearance

- Indoor/outdoor

- Rich, semi-gloss sheen

- Superior color and sheen retention after repeated heating

- Do not use in areas directly exposed to flames (e.g., inside of grills or fireplaces)

- 12 oz. Spray

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions2. Epifanes Clear Varnish

World famous, highest quality traditional tung oil marine spar varnish.Formulated with tung oil, phenolic and alkyd resins resulting in a finish that has superior flow, gloss, durability, and exceptional longevity.UV filters for superior protection with an ultra high gloss finishUsed in many applica...

Specs:

| Color | clear |

| Release date | July 2011 |

3. The Army Painter Anti Shine Matt Varnish for Miniature Painting - After Quickshade Matte Top Coat Acrylic Spray Varnish for Miniatures - Matte Finish Spray for Acrylic Model Paint, 400ml, Can

- TAILORED TO REMOVE SHINE AND GLOSSY LOOK : Removes shine after painted with Quickshade or acrylics

- BORN FROM GAMING: Get awesome painted plastic models or craft on the table for a great game!

- RETAINS METALLIC SHINE: Gives perfect matte finish while retaining shine from metal acrylic paint

- GIVES AN ELEGANT AND FINISHED LOOK: Make your miniatures look finished with this satin varnish spray

- WILL NOT CRACK AND CHANGE COLORS: Preserves all colors. If applied properly, it will never crack

- ACRYLIC, NONTOXIC - This varnish is Acrylic-based, transparent matte and dries very quickly

- LET PAINT DRY BEFORE USING: Let the Quickshade dry for minimum 48 hours before using the varnish

- APPLY IN A THIN COAT: Test on a model first before spraying the whole army

- IDEAL PAINT SEALER & CLEAR COAT SPRAY Retouch gloss of protruding details and protect your minis

- NOT IDEAL FOR: Do not use acrylic spray paint varnish in humid conditions and cold outdoor weather

Features:

Specs:

| Color | Anti Shine Matt |

| Height | 8 Inches |

| Length | 2.5 Inches |

| Size | 13.5 Fl Oz (Pack of 1) |

| Weight | 0.8377565956 Pounds |

| Width | 2.5 Inches |

4. Minwax 60910000 Wipe-On Poly Finish Clear, quart, Satin

Easy to apply - no drips or brush marksProtects wood against water, household chemicals, food stains and wearProvides a hand-rubbed lookProtects against water, household chemicals, food stains and wearMade of a high quality oil-based polyurethaneAvailable in Gloss or Satin

Specs:

| Color | Quart |

| Height | 7.75 Inches |

| Length | 3 Inches |

| Number of items | 1 |

| Size | Satin |

| Weight | 2 Pounds |

| Width | 3.5 Inches |

5. Minwax 63010444 Fast Drying Polyurethane Clear Finish, quart, Satin

Provides long-lasting beauty and protection to any interior wood surfaceAmong the most durable coatings for wood protectionIdeal for woodworking, furniture, doors, cabinets and floorsCan be used on both finished and Unfinished woodIt provides long-lasting protection and beauty to interior wood surfa...

Specs:

| Color | Quart |

| Height | 4.89 Inches |

| Length | 4.25 Inches |

| Number of items | 1 |

| Size | 1 Quart |

| Weight | 2.0499999982809 Pounds |

| Width | 4.25 Inches |

6. General Finishes Arm-R-Seal Oil Based Topcoat, 1 Quart, Semi-Gloss

- Arm-R-Seal topcoats are made with only the highest quality urethane resin

- These topcoats are extremely durable and long lasting

- They are formulated to be wiped on with a cloth or applied with a foam brush

Features:

Specs:

| Color | Semi-Gloss |

| Height | 5 Inches |

| Length | 5 Inches |

| Number of items | 1 |

| Size | 1 Quart |

| Weight | 1.99 Pounds |

| Width | 5 Inches |

7. General Finishes High Performance Water Based Topcoat, 1 Quart, Satin

- Do not apply clear topcoats over bright white paint, as yellowing may occur due to a reaction to the substrate. Light color paints may also experience yellowing due to topcoat application, but it will less noticeable.

- The hardest, most durable consumer polyurethane top coat on the market today

- Dry Time Between Coats is only 1 to 2 Hours

- Interior use only

Features:

Specs:

| Color | Satin |

| Height | 5 Inches |

| Length | 5 Inches |

| Number of items | 1 |

| Size | 1 Quart |

| Weight | 2.4 Pounds |

| Width | 5 Inches |

8. Epifanes Clear Varnish (1000 ml)

- World famous, highest quality traditional tung oil marine spar varnish. Dry time at 65 degree Fahrenheit: Dry in 12 hours, recoatable in 24 hours

- Formulated with tung oil, phenolic and alkyd resins resulting in a finish that has superior flow, gloss, durability, and exceptional longevity.

- UV filters for superior protection with an ultra high gloss finish

- Used in many applications, both exterior and interior, household or marine, brushed, sprayed, or rolled and tipped.

- Use on new wood or restoring old wood to a deep clear finish, softwood or hardwood, marine or household applications.

Features:

Specs:

| Color | clear |

| Height | 7.87 Inches |

| Length | 4.4 Inches |

| Release date | July 2011 |

| Size | 1000 ml |

| Weight | 2 Pounds |

| Width | 4.4 Inches |

9. General Finishes Wood Bowl Finish, 1 Quart

- Safe topcoat on wooden bowls, cups, spoons, decorative wood countertops or other wood surfaces that come into contact with food

- Created to be safe on wood surfaces that contacts food

- Not for actively used butcher block counter tops that are used for chopping and cutting

Features:

Specs:

| Color | Clear |

| Height | 5 Inches |

| Length | 5 Inches |

| Number of items | 1 |

| Size | 1 Quart |

| Weight | 2.1 Pounds |

| Width | 5 Inches |

10. Sunnyside Corporation 87232S Boiled Linseed Oil, Quart

Penetrates and protects wood creating a quality finish for wood furniture and antiquesEnhances natural wood tones and grain patterns of woodExtends and fortifies oil-based paints and coatingsApply to unfinished wood onlyFast drying, usually within 12-18 hours depending on conditionsDerived From The ...

Specs:

| Color | Boiled Linseed Oil |

| Height | 7.44 Inches |

| Length | 2.39 Inches |

| Number of items | 1 |

| Size | Quart |

| Width | 4.59 Inches |

11. EPOXY Resin 1 Gallon Kit. for Super Gloss Coating and TABLETOPS

- Super Gloss Durable Finish

- Water resistant

- Self leveling

- Odorless

- Detailed instruction included with each kit

Features:

Specs:

| Color | Clear |

| Height | 5 Inches |

| Length | 10 Inches |

| Weight | 8 Pounds |

| Width | 10 Inches |

12. Formbys 30013 Furniture Refinisher, 32-Ounce

- Easily dissolves old varnish, lacquer, and shellac

- No sanding or scraping necessary

- Finish with an application of Tung Oil

- Easily dissolves old varnish, lacquer and shellac

- No sanding or scraping

- With the help of fine steel wool, old finish is melted down completely without taking color from wood or raising veneers

- After surface dries, a protective finish of Tung oil should be applied

- 32-Ounce

Features:

Specs:

| Height | 8 Inches |

| Length | 5 Inches |

| Number of items | 1 |

| Size | 32 oz |

| Weight | 2 Pounds |

| Width | 3 Inches |

13. Minwax 40910000 Wipe-On Poly Finish Clear, pint, Satin

Easy to apply - no drips or brush marksProtects wood against water, household chemicals, food stains and wearProvides a hand-rubbed lookProtects against water, household chemicals, food stains and wearMade of a high quality oil-based polyurethaneAvailable in Gloss or Satin

Specs:

| Color | Pint |

| Height | 6.75 Inches |

| Length | 2.5 Inches |

| Number of items | 1 |

| Size | Satin |

| Weight | 1.33 Pounds |

| Width | 2.75 Inches |

14. Minwax 657000000 Water-Based Sanding Sealer, Quart,Clear

- Seals wood grain

- Easy to sand

- Dries in one hour

- Use on unstained, bare wood floors, furniture, doors, and cabinets

- It seals wood grain and easy to sand

- Designed for use on unstained, bare wood floors, furniture, doors and cabinets

- Dries quickly, in one hour, for easy project completion

- It seals wood grain and easy to sand

- Designed for use on unstained, bare wood floors, furniture, doors and cabinets

- Dries quickly, in one hour, for easy project completion

Features:

Specs:

| Color | Quart |

| Height | 5 Inches |

| Length | 4.4 Inches |

| Number of items | 1 |

| Size | 1 Quart |

| Weight | 2.1164377152 Pounds |

| Width | 4.4 Inches |

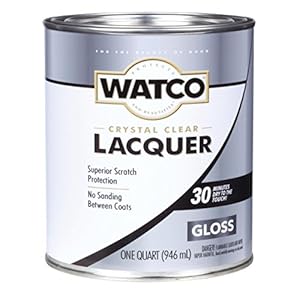

15. Watco 63041 Lacquer Clear Wood Finish, Quart, Clear Gloss

- Ideal for use on furniture, doors, cabinets and paneling; not recommended for floors or exterior surfaces

- Formulated for a higher clarity finish than polyurethane

- Dries to the touch in 1 hour and covers up to 290 sq ft

- Eliminates the need for wood filler and protects against scratches; no need to sand between coats

- Dries to a crystal-clear gloss with a lasting durable finish

- Apply to furniture, doors, cabinets and paneling

- Dries in 30 minutes and does not require sanding between coats

- Dries crystal-clear

- Durable wood finish and seal

- Fast-drying

Features:

Specs:

| Color | Clear Gloss |

| Height | 4.9 Inches |

| Length | 4.15 Inches |

| Number of items | 1 |

| Size | Quart |

| Weight | 2.19 Pounds |

| Width | 4.15 Inches |

16. Minwax 63205444 Helmsman Spar Urethane, quart, Satin

Contains UV blockers to reduce the sun's graying and fading effects.Forms a protective barrier against rain and moisture.Special oils allow the finish to expand and contract with the wood as seasons and temperatures change.Ideal for use on doors, windows, trim, bathroom cabinets, bar tops, kitchen c...

Specs:

| Color | Quart |

| Height | 4.89 Inches |

| Length | 4.25 Inches |

| Number of items | 1 |

| Size | 1 Quart |

| Weight | 2.20462262 Pounds |

| Width | 4.25 Inches |

17. Minwax 63200444 Helmsman Spar Urethane, quart, Gloss

Recommended Uses: furniture, woodwork, molding, cabinets, doors, paneling, accessoriesApplication Tool: natural bristle brushDry Time: 24 hours before normal useCleanup: mineral spirits or paint thinner following manufacturer's safety instructionsContains UV blockers to reduce the sun's graying and ...

Specs:

| Color | Quart |

| Height | 4.89 Inches |

| Length | 4.25 Inches |

| Number of items | 1 |

| Size | 1 Quart |

| Weight | 2 Pounds |

| Width | 4.25 Inches |

18. Tried and True Danish Oil, Pint

- Safe for Food & Skin Contact

- Free from Solvents, Dyes, Petrochemicals & VOCs

- Old-School Rustic Sheen

- Pure heat-treated linseed oil

- 100% Renewable Ingredients

Features:

Specs:

| Size | Pint |

19. Minwax 64444444 Polycrylic Protective Finish Water Based, quart, Semi-Gloss

- PROTECT WOOD SURFACES – Minwax Polycrylic Protective Finish protects and adds beauty to your interior wood projects, including woodwork, furniture, doors and cabinets. The clear top coat protects against scratches, spills, dirt and more.

- CRYSTAL CLEAR FINISH THAT LASTS – The crystal clear finished offered in this protective coating is ideal for use over all Minwax Oil-Based and Water-Based Stains and colors, as well as all wood species including light woods like maple, ash and birch.

- SEMI-GLOSS SHEEN – Give your wood projects a sleek finish with this semi-gloss clear varnish. It protects the natural beauty of the wood and offers a semi-shiny, sleek sheen for a bright, modern look. It’s non-yellowing, non-ambering and low odor.

- ULTRA FAST DRYING – Get more done with this protective poly coating. It’s a fast-drying clear coat, which allows for quick recoats after 2 hours, letting you get projects done faster. Be sure to apply with a high-quality synthetic bristle brush.

- EASY CLEAN UP – This water-based wood finish allows for easy soap and water clean-up, so you don’t have to stress about spills and big messes.

- Water clean-up

- Low odor, non-yellowing

- Fast drying

- Semi Gloss

- 1 quart

Features:

Specs:

| Color | Quart |

| Height | 4.9 Inches |

| Length | 4.3 Inches |

| Number of items | 1 |

| Size | 1 Quarts (Pack of 1) |

| Weight | 2.25 Pounds |

| Width | 4.9 Inches |

20. The Army Painter Anti Shine Matt Varnish for Miniature Painting - After Quickshade Matte Top Coat Acrylic Varnish for Miniatures - Matte Finish for Acrylic Model Paint, 18ml, Dropper Bottle

- 18 ml.

Features:

Specs:

| Height | 0.98425 Inches |

| Length | 3.1496 Inches |

| Number of items | 1 |

| Size | 0.6 Fl Oz (Pack of 1) |

| Weight | 0.02 Pounds |

| Width | 0.98425 Inches |

🎓 Reddit experts on household poly & varnishes

The comments and opinions expressed on this page are written exclusively by redditors. To provide you with the most relevant data, we sourced opinions from the most knowledgeable Reddit users based the total number of upvotes and downvotes received across comments on subreddits where household poly & varnishes are discussed. For your reference and for the sake of transparency, here are the specialists whose opinions mattered the most in our ranking.

For me, that would be dependent on several factors - I would block sand the headstock with about 220 grit, with the grain, until it's as smooth and blemish free as possible...

Then I would double check to make sure that the tuning keys have enough threads to tighten down properly without the thickness of the missing veneer. If they do, you're good to proceed, otherwise, you probably want to find a veneer, shape and glue it up and proceed with finishing. (you also would have the option of reaming out the holes and using a bushing, but that would weaken the headstock just a bit).

If you want a fairly exact match on the color, Stew-Mac has ColorTone Liquid Stains that can be mixed with lacquer (or polyurethane, if that's your choice, I'd personally go with lacquer as it's easiest to work with and polishes out better) - you can tint the clear finish (don't tint the whole can, you'll also want some clear to apply on top), and just brush on subsequent coats until the color is deep enough to match. a few (few in my world means about 10, but I'm extremely particular) coats of clear on top, block sand with 2000 grit paper, and hand polish and you're good to go.

Another option would be to stain the wood directly, but you may have a harder time getting the color to match. If you test on a scrap of similar wood, though, you can get it pretty honking close and the use the tinted clear to tweak it. That might be faster (stain first, then clear).

Whatever finish you decide to go with, be sure to pay careful attention to the wait time between coats and the recoat window. Layers have to thoroughly outgas between coats so that you don't trap solvents between layers - that's how you get bubbles of cloudy (blushed) clearcoats.

Refrain from casing it up as long as you can - let the finish air dry as long as you can stand it. OH, and you probably also want to wait at least a week after your last coat of clear before you crank down on the tuning key nuts to make sure that the finish has fully hardened - otherwise you'll get squishy little craters in the finish because it's still a little soft. Those things don't have to be torqued down like a car engine mounting bolt either, just hand snug is fine. It's your guitar, you can always revisit that in a couple of months anyway.

Best of luck with your project - we want pics when it's done!

Nope, although you might get away with it depending on your goals.

Finishing wood for outdoors is really difficult, largely because of the UV exposure. Almost any finish breaks down over time and needs reapplied every so often, but if the finish isn't UV-stabilized specifically for outdoor use, that process takes days or weeks instead of years.

The most protection you can give wood is paint, or a semi-opaque deck stain, which is pretty much the same thing. If you don't want to obscure the grain that much, you need to look at marine varnishes, since they're typically formulated for serious long-term exposure. Epifanes Classic is widely regarded as one of the best options, but any boat supply place will have other options. Follow the directions exactly, no matter how complex the coating schedule. "Spar urethane" from a hardware store, like Minwax Helmsman, is plenty waterproof and can handle a bit of sunlight, but it can't handle long-term daily exposure like the better finishes. Unfortunately, even those better finishes will eventually break down and need recoated.

Another option is to skip the finish entirely. Trees spend quite a lot of time outdoors, and perhaps unsurprisingly some species are quite good at it even once you strip off the bark. Ipe, osage orange, black locust, and teak are some of the best choices, and white oak, western red cedar, and black walnut are pretty decent as well. Those woods, with no finish at all, will survive longer than most wood finishes.

If you happened to make your marker out of a resilient wood, the Danish oil won't help much but also won't hurt. You could stick it outside now and likely be fine for a decade or two. If it's not one of those woods, spend some time putting a high-end marine varnish on. It'll still need touched up occasionally, but that'll give it a shot.

Ultimately, I hope you're not expecting a century of service out of this. Wood is great, but tombstones are usually granite for a reason.

As someone working through this but a few years ahead of you, I'll pass along the list of stuff I've bought and/or wish to buy...

Hand Tools

Power Tools

Also, there are fluids to consider

Of these, I'd focus on the hand tools, fluids, and the Dremel. You can always ask someone to buy you a saw for Christmas. If you have these things on hand, there probably won't be a job come along that you can't handle at some basic level. I'm assuming you don't need yard grooming tools, because that's an entirely different list.

I would suggest:

Basic process (You have the video to fallow, but these steps are general steps for almost all woodworking finish)

Other Options, instead of Laquer:

I pretty much use boiled linseed oil to finish everything I make. You can just wipe on with a brush or rag and it's basically impossible to mess up. It brings out the natural color and grain nice without looking overdone. Personally, I don't like clear coat unless it is satin or flat. I think shiny furniture takes away from the natural beauty and loses some of the grain in the glare. This satin clear coat works pretty good I've found and is water based and easy to clean up: https://www.amazon.com/Minwax-64444444-Polycrylic-Protective-Semi-Gloss/dp/B000PRNXNY I've used it on 5-6 tables now and I'm always happy with the look and durability. You can do 2-3 coats and sand with 220 briefly in between coats to get the finish super smooth.

Anyways, you have a really cool slab and it's going to make a beautiful table no matter how you decide to finish. :)

Thanks dude! And, yeah that's an awesome design, I think it'd make a cool deck too.

I'll let you in on a secret that took me forever to figure out: the best way to make masking / stencils is to get yourself some transparency sheets, like the kind used for overhead projectors in school, and then take a marker and draw what you want to spray through (best way to make stencils). Then take a 'wood burning kit' (which is just a low-heat soldering gun pretty much) and use it to "trace" your lines on the transparancy sheet, do it light and quick and it'll cut the parts out that you want - afterwards you'll be left with a mask or stencil that's much stronger than paper, easy to clean, and the wood engraver allows you to make more detailed and smoother cuts than if you were masking with tape, or cutting out of cardboard or card stock.

When you finish your painting, you'll want to give it a light coat of clear spray finish, and when that dries hit it with a coact of actual clear coat - I use minwax - that''s 'satin' (which is their way of saying 'matte') listed there but I prefer mine to be gloss. It's important that you hit it with the spray finish first, because it'll seal the paint, and the minwax may cause it to run if you don't. I use a lot of markers in my paintings and minwax will absolutely make them bleed and run if I don't seal them first.

You also want to seal it because the acrylic will easily chip off the deck

Like I said, also be aware that painting on a deck is A LOT different than painting on canvas, the deck will cause the acrylic to paint much faster than canvas so you lose that 'wet period' you normally have to blend paint.

Good luck, post a picture when you finish it! And feel free to drop me a line if you have any other questions.

Dowels and chopsticks with sandpaper wrapped around them, and a Dremel with a variety of stones. It's gonna be a labor of love.

Proluxe is good, but it's really just a deck stain. And the semitransparent is a water based acrylic... you're not gonna like the finish it gives you on that beautiful old hardwood. It'll look like plastic. I'd personally go with an Old Masters penetrating stain (you can go with a wiping stain if you wanna tone down the grain a little... wiping stain will give you a little more of the semitransparent look) followed by a spar finish (3 coats, applied with sponge brushes, light sand with 220 between coats - juuuuust kiss it with the sandpaper). It'll give the door a richer and longer lasting finish than a simple coat of deck stain, and the spar is UV protectant.

I'd use Evaporust or Metal Rescue on any of the ironwork that can be removed and allowed to soak (with both products, you strain the soak and pour it back into the jug - it's reusable several times). After the rust removal soak, clean with acetone and use a self-etching primer. For anything you can't remove and soak, use Rust Reformer after wire brushing instead of a simple primer for tough surfaces - it converts surface rust to magnetite to stabilize it. Then proceed with your black color coat. After the black, spray with a couple coats of satin clear. All the paints I linked are available at any auto parts store and Walmart, and I believe Home Depot carries Metal Rescue.

That's a gorgeous door. Take pictures and post a project gallery!

Edit: added that Proluxe semitransparent is water based.

Looks pretty easy. The basic steps are Sand, Seal, Stain, Finish

Okay, you've picked a pretty tricky first refinishing project. But lets get to it.

Legs: Lightly sand and use a shellac based primer. Shellac sticks to everything, so this will save you headache later. You won't need much, which is good, as shellac primer is a little expensive.

Top: Pine is a bitch to stain. Reading the description at Ikea's site, it would appear the top coat is lacquer. Which is good and honestly, a fine finish for the dining room. In large part because it is easy to refinish. Poly sucks for nice furniture just because of how tough it is. Anyway...

Start with something like this: http://www.amazon.com/Formbys-30013-Furniture-Refinisher-32-Ounce/dp/B0014JGFYG You want to be able to remove the top coat without mucking with the stain too much. There are other brands. Specifically look for something that disolves varnishes. Avoid full blown strippers. Follow the directions.

Once the top coat is gone, assess. If you're lucky, the stain is fine. Simply reapply another coat of lacquer. If you have to restain, you get some fun.

If the stain is mostly okay, you can try to touch up the problem spots. Understand that it may or may not work well. (Like I said, pine sucks here.) Trust your eyes and hands.

If the stain is more screwed, I'd lightly sand the whole thing. You probably won't get all of the stain out, but you can at least make it more even. Now apply a pre-stain conditioner. Then restain. Then lacquer.

Without the pre-stain conditioner, you will likely get blotching, which is how pine tends to fight you with stain. If you have more questions, fire away!

And Finally:

I'll need better, close up pictures of the scratches. You might, might might, MIGHT be able to simple apply a top coat of lacquer and have it clean up your scratches. Lacquer, like shellac, reactivates in the presence of solvent (lacquer thinner for lacquer, STRONG alcohol for shellac). This allows additional layers of finish to melt together with the previous finish. Again, if there are just light scratches, a little thinner on some steel wool rubbed gently over the whole surface and 2-3 new coats can cover up a lot of sins. I'd recommend not trying this without some very careful pictures for me to confirm it'll work.

I understand your wife's aesthetic concerns; a white kitchen really does brighten up a space, and the old wooden decor is extremely outdated and makes you feel like you're in the 80's nowadays. I recently repainted my kitchen cabinets as well: https://imgur.com/a/8zw3SZo

​

I bought General Finishes milk paint. You don't need any other base coat or stripping original paint; just put it right on top the old wood. https://www.amazon.com/gp/product/B00JUP1WLM/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

​

Topped it off with some topcoat: https://www.amazon.com/gp/product/B001DSZ3C8/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

​

Total paint cost about $160, and the additional paintbrushes/trays $30, so all in less than $200. It took me about 5 full (~8 hour) days; definitely a lot of work, but worth it for the value. Super happy with the end result given how cheap it was.

My recommended buying list for a new painter is:

Tools

Sprays

○ Grey is standard, white if you're painting a majority of light colors, and black if the majority is dark.

Brushes

○ Round 0

○ Round 1

○ Round 2

All in all it should be around $60 USD for the tools and about $40 USD for the brushes. However, this list gives you every tool you will need to get started and to continue with the hobby. Nt all of this is required, but it is nice to have.

This is just what I like to have on hand, this does not reflect the "perfect list". I hope it helps :)

For the wood, start with a Furniture Refinisher (Formbys's makes one). It's basically a low strength stripper and it allows you to clean up a lot of the damage without needed to completely strip the piece. It is incredible how much of the color fading, bleaching, and scratches that you can get rid of with refinisher. And it keeps as much of the original finish on that is still good so it protects the integrity of the piece. You don't want to strip and sand if you can help it because the entire piece will be veneer and it is very easy to wear through the top layer to the wood underneath and ruin it.

Speaking of, as another commenter mentioned that is not plywood, it is veneer. And I'm not sure it is oak. If you find out it is oak, be sure to look for a veneer that matches the quality and look of vintage oak, because it is not the same look as people use oak for now.

The top you may need to replace, or you may be able to spot fix. And the sides you may be able to gently coax/glue/clamp back into place. I would research veneer replacement and restoration to find out. Either way, you would only take off the very top layer (the thin veneer) and not the entire top and side, and that would be worst case scenario.

If you want to use this as an opportunity to learn beautiful wood finish, I can't recommend Charles Neil's Wood Finishing youtube channel enough. They are long, he's a talker, and he is amazing.

For the insides, I know nothing of electronics. I would probably try and vacuum it first before going to water. With restorations the trick is slow and steady. You do the least harsh method first and slightly upgrade aggressiveness if you need to. Much of the dust and dirt can be vacuumed out with a bristle attachment. When you say soap and water, I am assuming you mean slightly damp rag? Even then, I believe water can leave deposits, so make sure that is right.

Youtube has good videos, but make sure the person explains why you should use something or use a product. A lot of them rely on homespun wisdom that isn't really good advice (I already saw a bunch saying to clean with WD40 which is not a wood cleaner, don't do that). The pros will explain the reasons why and use it as a teaching moment. The home vloggers will just go through the process.

I'd encourage you to look in to Tried & True Danish oil. It's a pure linseed oil, so same idea as tung oil, but it's the oil that in my experience has changed the color of maple the least. Two or three coats of it applied according to the directions on the container will give you a nice subtle satin sheen.

As for blotchy issues, I typically only see that as an issue when someone tries to color maple with a big box store type wood stain or something like that. If you want to color the maple, I'd recommend Transtint dyes, but since you said you want to keep in natural on show off the grain, immaculate surface prep + Tried and True should get you where you need to go.

https://www.amazon.com/Tried-True-Danish-Oil-Pint/dp/B0155AUTG4

depending on how rough it feels I would suggest starting with an 80g or 100g and then finishing with 120g and 220g. You can skip the first one if it is not super rough. Get one of those sanding sponges with the different angles on them. That will be easier on you hand than just sand paper. Becasue of the shape you'll want something that you can wipe or spray on. Use 4-5 thin coats. The easiest/cheapest option would be a wipe on poly or even better an Aerosol Spar Urethane. EDIT Also, sand lightly in between coats with 220 or higher. This helps the next coat stick.

You might also consider trying to fix a few of those larger cracks by filling them in with a two part epoxy

Good luck! It will be a nice surprise for her when she returns.

Epifanes varnish. Use the Wood Finish Gloss to build up a smooth surface without sanding between each coat. Sand after a few coats and apply the Clear varnish for a stunning finish. It will give you the rich color you're after and the clear super smooth high gloss finish you want. Plus it has super UV and water resistance.

http://www.amazon.com/gp/aw/d/B005ADX4N2/ref=pd_aw_sims_1?pi=SY115&simLd=1&dpPl=1&dpID=51QTN7uDRlL._SY200_QL15_&slTrans=0&ref=nsDpPl

http://www.amazon.com/Epifanes-ECVSA-Clear-Varnish/dp/B005ADWQ9U

I chose not to. I might regret that decision but my logic was the bed won't get handled enough to warrant a poly. Not like a floor, desk, table, cabinet, etc. Mattress and blankets cover most of it. I maybe should have done it just to be safe. Still easy enough to apply if I change my mind. I'm definitely going with a wipe on poly. Minwax makes an awesome one I've used before.

After you paint minis that you intend to play with it’s a good idea to seal them with varnish. It protects the paint job otherwise you can start to wear it down over time.

Generally, matte varnish is best unless you want really shiny - take a look at the army painter spray here:

https://www.amazon.com/Army-Painter-CP3003-Anti-Shine-Varnish/dp/B005WH4C2S/ref=mp_s_a_1_14?keywords=the+army+painter&qid=1555252570&s=gateway&sr=8-14

The reason you want to do it before basing them is the varnish will cloud up the clear base, so you want to get them all finished before re-basing them.

Hope this helps!

The best clear finish for wood, bar none, is this stuff: https://www.amazon.com/Epifanes-ECVSA-Clear-Varnish/dp/B005ADWQ9U

Highly recommend. Goes on smooth, and extremely durable. Also great customer support. You can contact the mfg if you have questions about application.

I spent about $1300 in walnut (103 BF 8/4", 24 BF 4/4") and $60 on the poplar (31 BF 4/4"). I way overbought on the walnut and probably still have 30-40 board feet left over (only 8/4") since I bought extra to pick out the best sections of each board.

The bolts aren't visible from the outside. Here's another picture of a test joint I did so you can see how the bolts work better https://imgur.com/a/O2lhpwe which I got from Rockler https://www.rockler.com/bed-rail-connection-system.

I've slept on the bed for about 3 months before I put the finish on it (Arm-R-Seal https://www.amazon.com/gp/product/B00IKNIDE4/) so I'm not concerned about the dowels breaking. Plus if they do break it's easy enough to take apart and put new dowels in or if I wanted to look into a metal rod instead of dowels.

Yes it's a Leesa mattress and I've been happy with it for the 2 years I've had it.

Yeah I patched the big voids with mortar. You can see a slight difference in color but it's not bad at all. My sink is ground/polished down to the point that there is a lot of exposed aggregate (and the surface had a shine before the epoxy, I guess from the polished silicon in the sand?), so there's a lot going on anyway.

If you are leaving any voids (which is fine, just make sure they can drain so that water doesn't sit in them), make sure to thoroughly vacuum them so there's no cement dust that could come loose.

I (think I) used this one: http://www.amazon.com/Finish-Varnish-Provides-Gorgeous-Appearance/dp/B000PEGLBS

Here's a pic of the sink; it looks better in person :) http://imgur.com/a/k1lwZ#9

I would be very careful with your decision. A countertop can be considered a food-contact surface, yes? You should strongly consider a food-grade sealer. Most sealers are highly toxic.

I recommend using a food-grade varnish. It’s far more durable and long-lasting than mineral oil, but not as much so as other sealers.

[Here is my favorite for cutting boards and such. ](General Finishes SBQT Salad Bowl Finish, 1 quart https://www.amazon.com/dp/B001DSXD7A/ref=cm_sw_r_cp_api_i_lJn9AbRCA13JH) It isn’t cheap, but eating toxic substances won’t end up being cheap either.

Edit: hopefully a working link?

Btw: it’s waaaay cheaper anywhere else but amazon, for some reason.

this one, but im thinking of trying another in the future, its great for smaller projects but in a large application like this i couldn't fend of the micro bubbles to save my life. the smaller stuff i can put in my pressure pot and be done with it.

https://www.amazon.com/gp/product/B00NLPCA5Y/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1

Thank you very much! I did the fast-drying - I almost exclusively use that product for poly.

The wax was a paste wax to buff the final finish and clean up any imperfections the poly might have left. It's similar to a wet sanding, without getting too technical. I used 0000 steel wool and put the steel wool in the wax, buffed it onto the box, then let it sit for a minute or two, and then removed the wax and buffed it with a shop(lint free) towel.

http://www.amazon.com/Johnson-Fine-Wood-Paste-00203/dp/B0000DIWIM

The humidor I made out of Tiger Maple with a Spanish Cedar lining. It's approximately 6' tall, 2.5' wide, and 1.5' deep. I'll link some pictures for you!

Edit1 Response: I used the MinWax sanding Sealer, that comes in the white can: http://www.amazon.com/Minwax-65700-Water-Based-Sanding-Sealer/dp/B004Y6TTKI

Edit2 Response: So I sanded the box with 150, 220, 400, and 800 with my orbital until it was as smooth as I could get it. With Zebrawood it seems like the grain stands up, and I could be using the wrong term, but part of the wood will pop up with almost small slivers, that will need to be buffed out. Essentially the grain was raised up and it really only does it on the first coat that gets applied. If you ever work with Zebrawood you'll know exactly what I'm saying - one of those things that's hard to explain without a sample in front of me.

FYI - I'm more than happy to answer any of your questions!

I personally love lacquer for finish watco brushing lacquer is my go to. It lays down nice with a good brush and it dries fast way faster than poly and hold up almost as well. It doesn’t have the water resiliency as poly. One tip I after final coat rub the surface with a brown paper bag take out the dust nibs without dulling the finish.

I think you can get some epoxy resin to skim the top.

EPOXY RESIN CRYSTAL CLEAR 1 Gallon Kit. FOR SUPER GLOSS COATING AND TABLETOPS https://www.amazon.com/dp/B00NLPCA5Y/ref=cm_sw_r_cp_api_i_ed4bBb2D7YJGZ

Army Painter Matte Spray Varnish is what I use.

It's actually great to use on top of Gloss Varnish, since the gloss goes on thicker and does a good job of protecting the mini.

Matte on top of gloss will appear matte.

I haven't used it yet, but I'm about to try This and then some of This on top of some patio furniture. It's used on boats and is highly recommended. I hope it works.

I recently bought a bandsaw : Rikon 14" Deluxe so I needed a project that required a bunch of resaw work. What better than a chest of drawers?

Overall this chest of drawers took around 70 hours to complete, mostly because I didn't know what I was doing. I put a few layers of General Finishes Satin Polyurethane on all sides and the top.

I made it completely from scratch, and it was intended to just be a practice piece. I've never made drawers before, and never resawn wood before, so it was a great learning experience.

Comments? Criticisms? Let me know what you think!

Vallejo Matt Model Color Varnish, 17ml https://www.amazon.com/dp/B000PH9JPA/ref=cm_sw_r_cp_apa_i_4ZWqDbN193MQG is a good one.

I use The Army Painter Anti Shine Matte Varnish https://www.amazon.com/dp/B007QW3M0U/ref=cm_sw_r_cp_apa_i_z1WqDb9D0KQZX. Because they had it at my local shop, it dries fast and I like brushing it on to control the thickness and honestly it doesn't take long.

Before you use a matte varnish use a gloss one it's a better protector. I do 2 thin coats of gloss then 2 thin coats of matte.

Gloss varnish- Vallejo Acrylic Paint, Gloss Varnish https://www.amazon.com/dp/B001JJZDSK/ref=cm_sw_r_cp_apa_i_82WqDb58V9HGK

Why do you think spar is more effort than poly, and why do you think it will take longer?

I stopped using normal spar urethane since they changed the formula to comply with the new VOC regulations here in the USA - it simply isn't what it used to be.

Lately, I only use Ephiphanes on my outdoor projects. It is really thick, but I thin it a good deal, and use multiple thin coats (just like poly). It is expensive, but worth it.

A clear pour over epoxy would be best. The water base varnish would not stand the test of time and you would eventually have the same peeling problem. Epoxy is bulletproof and isn't that hard to use. Something like this would work well.

Pour some epoxy over the top. It looks great and will totally protect the surface.

http://www.amazon.com/Pour-On-Varnish-Provides-Gorgeous-Appearance/dp/B000PEGLBS

Give me minute to look up the video I saw but it is not that hard and the acid is very dilute. It takes less money than powdercoating and the finish is amazing. Plus it can be used to do multicolor effects. The bar top finish is an epoxy based finish. Ill look for a link brb.

Ok here it is the bartop finish

http://www.amazon.com/gp/aw/d/B000PEGLBS?pc_redir=1396668298&robot_redir=1

And here is anodizing.

This guy is monotone but he is very clear.

http://youtu.be/sI-oiBKAyOY

http://youtu.be/m802YwZCj04

Multicolor mask technique

http://youtu.be/8OpewWuDJJE

I already etch boards this is not much more difficult

Plus you can do photoemulsion resist and do really crazy graphics.

I will be doing some of this in the next few months and will post my results.

Helmsman Spar. It's a wood varnish designed for outdoor/marine use, works great for bar tops and tables because it holds up well against moisture. 3-4 coats is usually enough. I recently built a bar and used this and it looks amazing. No worries if I forget to use a coaster under a sweating glass, it never rings.

I use https://www.amazon.com/Minwax-63200-Helmsman-Urethane-Finish/dp/B000Y4II3I/ref=sr_1_6?ie=UTF8&qid=1473080884&sr=8-6&keywords=spar+varnish whenever I'm concerned about yellowing, say from the sunlight from a window. It's formulated to block UV which is what causes fading and yellowing.

It will not give you the finest furniture lacquer quality finish, but a very nice finish is doable if you take care with multiple coats, sand between coats, use a proper tack rag, maybe thin a tiny bit with mineral spirits to get thinner coats. Finish is tough and you don't have to worry about damage from the misc stuff that gets thrown on tables.

The only drawback is that it is oil based, so you need good ventilation when working with it and it takes a few days to lose the smell completely.

Please post a photo of the finished project in reply to this comment.

If I were you, I would use 2 x 12" joist material. Laminate two lengths of the material together such that it becomes a 4 x 12". Then, you will want to have a support as /u/wbgraphic suggests out of the same 4 x 12 material. Since this will be outside (from the sounds of it), you will want to use titebond III and then finish the entire assembly in marine varnish for durability (epifanes http://www.amazon.com/Epifanes-ECVSA-Clear-Varnish/dp/B005ADWQ9U is some hardcore shit). I would also suggest that the entire support structure should be attached not just by lagging to one side of the pole, but via a complete wrap around the pole either with steel cable or some other such structure.

100lbs isn't that much weight, but if you're going to use it as a heavy bag for martial arts, there are quite a few lateral forces to contend with and not just static load. Research how heavy signs are hung from buildings using a boom arm and you'll have a better idea.

Yeah varnish can be weird, every brand is different I use to love this reaper brand but can’t find it anymore but the army painter stuff I’m using is a close second.

Hobby Anti-shine Paint Pot https://www.amazon.com/dp/B007QW3M0U/ref=cm_sw_r_cp_api_i_UcRPCb3HW1Z6P

Then you have peeps who use unconventional types of varnish like pine-sol or something like that through an air brush. Although I can’t remember if it was pine-sol that I read that they used. I think it’s weird but if works for them to each their own.

Exterior, Spar, or marine grade varnishes have UV blockers (usually) in them that normal interior finishes do not.

Epifanes is very popular and performed the best in a test in FWW #205

Nice work! I, too, started painting minis with Gloomhaven.

Don't try and seal them with clear nail polish, like an idiot I know. Get a spray can of Army Painter or something.

Something like this? Table looks amazing.

https://www.amazon.com/General-Finishes-SGQT-Arm-R-Seal-Semi-Gloss/dp/B00IKNIDE4/ref=sr_1_29?srs=3029218011&ie=UTF8&qid=1494281646&sr=8-29

I use:

EPOXY Resin Crystal Clear 1 Gallon Kit. for Super Gloss Coating and TABLETOPS

https://www.amazon.com/dp/B00NLPCA5Y/ref=cm_sw_r_cp_api_i_yPtYDbX2C34AW

Minwax Poly is this what you're talking about and if so, should I get the regular or water based. Also which size, quart or half a pint. There is also an aerosol version of the regular version and I was wondering if that is just as good. Thanks

Acacia us beautiful stuff.

I've used this liquid epoxy before for an outdoor sign I made, held up OK but in direct UV, it will need recoating every so often.

do a small test batch on scrap to get process down

For inside, should be fine

https://www.amazon.com/Finish-Varnish-Provides-Gorgeous-Appearance/dp/B000PEGLBS

Gerneal Finishes Salad Bowl Finish

It recommends 3 coats, but I think I ended up with 5, sanding with finish grade steel wool between coats.

This is the second one I made, the first was for my oldest son about 4 years ago. The finish faded in luster considerably, so I thought adding a few more coats would help prolong the gleam.

you will want to use an epoxy finish, wood itself is obviously not water tight, and any typical finish like polyurethane are not permanently water tight. So you basicly need to coat the wood in clear plastic, atleast on the inside.

this would work https://www.amazon.com/Finish-Varnish-Provides-Gorgeous-Appearance/dp/B000PEGLBS

I would suggest practicing on a piece of scrap wood if you do want to add color. I think it look lovely as is though!

As for the finish, I use this:

Minwax 64444444 Polycrylic Protective Finish Water Based, quart, Semi-Gloss https://www.amazon.com/dp/B000PRNXNY/ref=cm_sw_r_cp_apa_i_sYPDDbDE4ZEJT

With this brush:

Minwax 427320008 Manway Polycyclic 2" Trim-Polyester/Nylon Blend Brush/Roller/Applicator, 2 inch, White https://www.amazon.com/dp/B01LBFR8T8/ref=cm_sw_r_cp_apa_i_9ZPDDbCF4N6BQ

Is this the kind of oil you'd use? I'm not familiar with this at all but it's big if true!

https://smile.amazon.com/SUNNYSIDE-CORPORATION-87232-1-Quart-Linseed/dp/B000C016PG/ref=sr_1_2?ie=UTF8&qid=1524592233&sr=8-2&keywords=boiled+linseed+oil

The full guide:

http://www.autogeekonline.net/forum/show-n-shine/19021-headlight-restoration-new-uv-sealant-idea.html

I would stain first, and then use a high quality spar varnish like Epifanes to seal, waterproof, and UV protect the final product.

Yeah, especially to protect the (I'm assuming) non-oil-based, less-durable coats of paint underneath. http://www.amazon.com/Finish-Varnish-Provides-Gorgeous-Appearance/dp/B000PEGLBS/ref=sr_1_2?ie=UTF8&s=arts-crafts&qid=1301373510&sr=1-2

I am looking for a natural oil finish and I want to avoid toxic substances and fumes. I tried food grade white mineral oil but the surface is still greasy a week later (its possible i did not put it on correctly). I saw some forum posts that people claimed its because mineral oil is a non-drying oil and it will always feel that way. So far this is what I have come up with Tried & True Oil and Walrus Oil has anyone used either of these or have other suggestions?

I did. I found that sealing it with three coats of Shellac and finishing it with something like General Finishes Arm-R-Seal Semi-Gloss seemed to work very well

In case anyone wanted detailed instructions, I followed these steps: http://www.buildyourownpokertables.com/how-to-build-an-octagon-racetrack-poker-table

Cup Holders: http://www.amazon.com/gp/product/B009FAMCCA/ref=oh_aui_detailpage_o02_s00?ie=UTF8&psc=1

Playing Cloth: http://www.amazon.com/gp/product/B009EU36SA/ref=oh_aui_detailpage_o03_s00?ie=UTF8&psc=1

Stain: Rust-Oleum Wood Stain Dark Walnut http://amzn.com/B00714KDV4

Polyurethane: Minwax Fast Drying Clear Satin http://amzn.com/B000VZLF58

Thanks for the reply! Is this a good one?

https://www.amazon.com/gp/offer-listing/B001OBMDXQ/ref=olp_twister_child?ie=UTF8&mv_color_name=1&mv_size_name=1&mv_style_name=0

General Finishes “wood bowl finish”

GF products are excellent.

General Finishes SBQT Wood Bowl Finish 1 Quart https://www.amazon.com/dp/B001DSXD7A/ref=cm_sw_r_cp_api_i_cKb1DbBH7NM9C

Sweet! Is this basically what I'm looking for?

https://www.amazon.com/General-Finishes-QTHS-Performance-Topcoat/dp/B001DSZ3C8/ref=sr_1_6?s=hi&ie=UTF8&qid=1493682698&sr=1-6&keywords=general+finishes

That's fine but it's gloss. You're probably looking for satin finish. Not gloss. https://www.amazon.ca/Minwax-63010-Drying-Polyurethane-Finish/dp/B000VZLF58 something like this would work if you mix it 1:1 with mineral spirits. That's what I did.

I would put a layer of epoxy coating on top of the whole thing. Something like this should be available at a local big box store.

http://www.amazon.com/Pour-On-Varnish-Provides-Gorgeous-Appearance/dp/B000PEGLBS

They might last longer than you think, but if you are looking to add some protection, just use something like this

Need to lube that pretty lady up.

I made mine out of cypress (1 with a cedar inlay and cedar plugs) and treated them with Waterlox Marine Sealer and I think I'll do something different for the next ones. After 9 months and 2-3 coats on everything, I'm already starting to get some silvering. I think on the next set (that isn't painted) I'll try Epifanes Clear Varnish

An alternative to shellac would be wipe-on polyurethane. This is the stuff I use, works like a charm. Goes on thin so you don't have to worry about drips or runs. It does darken the wood a little bit since it's oil based, but that means that the grain and any figure also pops.

Minwax 60910000 Wipe-On Poly Finish Clear, quart, Satin https://www.amazon.com/dp/B001OBMDXQ/ref=cm_sw_r_cp_api_i_4iGACbZFG5Q08

I could never seem to get a great finish with minwax polly, but then I switched to the Arm-R-Seal polly and it was night and day. very smooth and just all around a higher quality finish

I would use spar varnish with UV blockers, like a marine finish meant for boats, for example this one:

https://www.amazon.com/Epifanes-ECVSA-Clear-Varnish/dp/B005ADWQ9U?th=1&psc=1

So the wood conditioner was just the standard Minwax Pre-Stain Wood Conditioner

https://www.amazon.com/Minwax-41500000-Pre-Stain-Wood-Conditioner/dp/B000C02AHY

For the poly, I plan on using some Minwax Polyurethane in clear satin

https://www.amazon.com/Minwax-63010444-Drying-Polyurethane-Finish/dp/B000VZLF58/

I know oil-based poly will leave a slight amber look as well...

[this](http://www.Minwax.com/ 63200444 Helmsman Spar Urethane, quart, Gloss https://www.amazon.com/dp/B000Y4II3I/ref=cm_sw_r_cp_apa_i_bi11BbAWDC6M3) is the one I got. Make sure it's not the water based one. And then mix it with mineral spirits. Most diys call for a 50/50 mix of both

https://www.hidplanet.com/forums/forum/general-discussion/shrouds-ccfl%C2%92s-angel-eyes-painting/41723-headlamp-uv-protector-urethane?p=675308#post675308

Epoxy is a decent idea, but I'd add a couple of coats of good spar varnish on top of that. At that point, it doesn't much matter what type of wood you use.

Sure! I looked into it a while back for a project, but I never got around to the project.

Here's a website with direction directions:

http://www.personal.utulsa.edu/~marc-carlson/horn/dhorn.html

And here's the varnish:

https://smile.amazon.com/General-Finishes-SBQT-Finish-Quart/dp/B001DSXD7A/ref=mp_s_a_1_3?keywords=salad+bowl+varnish&qid=1562788235&s=gateway&sr=8-3

If you are having people sign the bare wood and then you want to cover it with something glossy i suggest epoxy. Something like this should do the trick. Check youtube for tutorials on how to use it, but it is fairly simple.

Can you order off Amazon? https://www.amazon.com/Epifanes-Clear-Varnish-1000-ml/dp/B005ADWKTG/ref=sr_1_1

No finish yet, but I was planning to use this marine grade varnish once the table top is on.

https://www.amazon.com/gp/product/B005ADWKTG

No stain, because Jupiter is a variation of browns.

helmsman is what I like to use.

Just grab a decent brush when you buy it and brush with the grain

maybe this? http://www.amazon.com/Finish-Varnish-Provides-Gorgeous-Appearance/dp/B000PEGLBS

just buy the miniwax wipe on polyurethane.

https://www.amazon.com/Minwax-40910000-Wipe-Finish-Clear/dp/B000VZJGPO

https://www.amazon.com/Resin-Crystal-Gallon-Coating-TABLETOPS/dp/B00NLPCA5Y?keywords=Crystal+clear+epoxy+1+gallon&qid=1537575262&sr=8-2&ref=mp_s_a_1_2 this is one I'll be using

From the translation, its just a solvent based urethane finish. This would be similar, https://www.amazon.com/dp/B000Y4II3I. There are lots of manufacturers of solvent based urethane finishes though.

https://www.amazon.com/EPOXY-CRYSTAL-Gallon-COATING-TABLETOPS/dp/B00NLPCA5Y/ref=sr_1_fkmr0_2?ie=UTF8&qid=1480726174&sr=8-2-fkmr0&keywords=countertop+epoxy+east+coast+resins

I used this poly:

https://www.amazon.com/dp/B000VZLF58/ref=asc_df_B000VZLF585149432/?tag=hyprod-20&creative=394997&creativeASIN=B000VZLF58&linkCode=df0&hvadid=198071503086&hvpos=1o4&hvnetw=g&hvrand=8167882762226370903&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9011703&hvtargid=pla-349434744939

and this paint:

https://www.lowes.com/pd/Olympic-Assure-Black-Flat-Latex-Interior-Paint-and-Primer-in-One-Actual-Net-Contents-128-fl-oz/4764166

The paint I used is paint+primer.

Seven coats of Semi-Gloss Arm-R-Seal.

https://www.amazon.com/Painter-CP3003-Anti-Shine-Matte-Varnish/dp/B005WH4C2S

What if you embedded the flowers in epoxy resin similar to this countertop

This kind!

https://www.amazon.com/gp/product/B00NLPCA5Y/ref=oh_aui_detailpage_o08_s00?ie=UTF8&psc=1

You might check out General Finishes Waterbased Poly - Non-affiliated Amazon link.

There are others but this one gets good reviews. The only downside to WB poly is the lack of depth of color in the finished products over oil based. Make some samples before you finish your desktop.

I'm not 100% sure but if anyone is wondering...

This is the kind of product they used to cover the sprinkles:

http://www.amazon.com/Pour-On-Varnish-Provides-Gorgeous-Appearance/dp/B000PEGLBS

It's not very easy to use though. After applying an even layer, air bubbles will appear and you need to burst them with a torch.

Fuck buying at lowes, you can get a gallon of epoxy on amazon for 48 bucks + shipping. https://www.amazon.com/gp/aw/d/B00NLPCA5Y/

Poly will. You can mess around with spar/long oil varnishes, or you can just do it right the first time and stop fucking around

To all the makers out there buying this "Turbo Glow" material from another supplier thus resulting in what I think is an inflated price. Now I could be wrong but all this stuff is, is a mixture of a glow powder

(https://www.amazon.com/dp/B01K0DQXD4/ref=twister_B01K0DQTM4?_encoding=UTF8&psc=1)

and some type of or something similar to a clear epoxy resin

(https://www.amazon.com/gp/product/B00NLPCA5Y/ref=ox_sc_saved_title_8?smid=AWNIMR5FR1N5J&psc=1)

placed into a block mold allowed to harden then cut into sections. The brittle nature of this material is probably dependent on how much powder is used. The more you use the brighter and more brittle it will be.

Now this is just my theory on "Turbo Glow" again I could be wrong. In any case I intend to use this method for future projects of mine, take it or leave it.