(Part 2) Best products from r/CNC

We found 20 comments on r/CNC discussing the most recommended products. We ran sentiment analysis on each of these comments to determine how redditors feel about different products. We found 99 products and ranked them based on the amount of positive reactions they received. Here are the products ranked 21-40. You can also go back to the previous section.

21. Haimer 80.960.00 Zero Master Analog Sensor

- 3-dimensional edge finder locates in X,Y and Z axis

- Measure work piece dimensions

- 1 Short Probe Tip Included w/ Sensor

- Measure surface flatness

- No subtracting indicator tip diameter = NO MATH!

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions22. Smooth-Sil 940 Food Grade Mold Making Silicone Rubber - Trial Unit

Suitable for Food Grade applications (See Technical Bulletin) - Great for making baking molds and trays, ice trays, casting butter, chocolate, fondant and other applications used to produce foods.Shore 40A HardnessMix Ratio: 100A:10B by weight (requires digital gram scale)Pot Life: 30 minutes - Cure...

▼ Read Reddit mentions

▼ Read Reddit mentions23. Witbot T8 380mm Stainless Steel Lead Screw+Copper Nut+Coupling Shaft+Mounted Ball Bearing Block Set for 3D Printer Parts

- Lead Screw: Diameter: 8mm, Pitch: 2mm, Length: 380mm

- Nut: Diameter: 8mm, Pitch: 2mm

- Mounted Ball Bearing: Bore diameter: 8mm

- Shaft Coupling: Shaft: 5 x 8 mm, Length: 25 mm, Diameter: 20 mm

- Widely use in 3d printer and cnc machine

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions24. Taishi 2 Axis Digital Readout DRO for Milling Lathe Machine with Precision Linear Scale

This kits includes 2 axis dro and 2pcs normal size linear scale,complete dro kitsIt is a mutlifunctional 2 axis DRO can be use on lathe machine, mill machine and other machinesThe linear scale must choose from 50-1000mm travel length, for over 1000mm ,it cost extraPlease leave a massage what travel ...

▼ Read Reddit mentions

▼ Read Reddit mentions25. Martin Gear Rack, 14.5 Degree Pressure Angle, 6 feet Long, High Alloy Steel, Inch

- Gear rack for use with spur gear pinion to convert rotary motion into linear motion

- High alloy steel for strength and durability

- Pressure angle of 14.5 degrees for smoother, quieter movement and lower frictional forces

- Rack length sized for up to 6' of linear movement from rotary motion

- Meets AGMA commercial class standards

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions26. Boston Gear L20206 Rack Gear, 20 Degree Pressure Angle, 20 Pitch, 6.0 feet long, Steel

- Gear rack for use with spur gear pinion (not included) to convert rotary motion into linear motion

- High alloy steel for strength and durability

- 20 degree pressure angle for higher load-carrying capacity than 14.5 degree pressure angle

- 6' long, 20 teeth per foot

- 0.50" face width and 0.50" overall rack thickness

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions27. Liberty 2960SL Nitrile Liquid Proof Unsupported Glove, Chemical Resistant, 15 mil Thickness, 13" Length, X-Large, Green (Pack of 12)

- Embossed grip on palm and fingers

- Made of nitrile

- Chemical resistant

- X-large size

- Measures 13-inches length by 15-mil thickness

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions28. Venom Steel Nitrile Gloves, Rip Resistant Disposable Latex Free Black Gloves, 2 Layer Gloves, 6 mil Thick, X-Large (Pack of 500)

- Venom Steel nitrile rubber gloves provide 2 layers of protection for incredible rip, tear, puncture, and chemical resistance

- Heavy duty disposable gloves are latex free and made of 2 layers of black and white nitrile rubber that help identify breakthrough

- 6 mil thickness is 70 percent thicker than common disposable exam gloves, making these great mechanic gloves or cleaning gloves

- Venom Steel black nitrile rubber gloves help protect your hands from grease, grime, dirt, oil, fuels, nicks, scrapes and more

- Unlike latex gloves, these nitrile gloves are latex free | Venom Steel disposable gloves are also powder free and fully textured for better grip than standard medical gloves

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions29. Nitto (Permacel) P-02 Double Coated Kraft Paper Tape: 1 in. x 36 yds. (White)

Nitto P-02 Double-Sided Kraft Paper Tape is a highly versatile, 2-sided flatback paper tape with extremely aggressive adhesion, making it ideal for various holding, mounting, splicing, fastening and laminating applications.Nitto P-02, previously known as Permacel P-02, is made from paper that has be...

▼ Read Reddit mentions

▼ Read Reddit mentions30. Humility Is the New Smart: Rethinking Human Excellence in the Smart Machine Age

- Kids Can Press

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions31. PORTER-CABLE Router, Fixed Base, 11-Amp (690LR)

11-amp motor producing 1-3/4 peak horsepower27,500 revolutions-per-minute single-speed motorPrecision machined aluminum motor housing and baseCam-lock lever enables simple coarse height adjustments and motor releaseMicrometer depth adjuster accurate to 1/128-inch11-amp motor producing 1-3/4 peak hor...

▼ Read Reddit mentions

▼ Read Reddit mentions32. Yonico 32210-SC 1/8-Inch Dia. 2 Flute Downcut Spiral End Mill CNC Router Bit 1/4-Inch Shank

- Laminate or veneer-finish plunging and dadoing.

- For standard CNC milling and routing where a clean top surface edge of material is required

- Premium C3 micro-grain solid tungsten carbide for a high-performance industrial quality tool

- For use on CNC, table mount and handheld routers

- Polished to a mirror finish from a solid carbide rod for precision & accuracy

Features:

▼ Read Reddit mentions

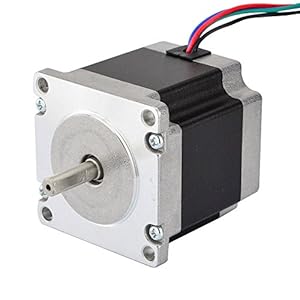

▼ Read Reddit mentions33. STEPPERONLINE Nema 23 CNC Stepper Motor 2.8A 178.5oz.in/1.26Nm CNC Stepping Motor DIY CNC Mill

Higher Torque1.26Nm(178.5oz.in) holding torqueNEMA 23 bipolar 2.24"x2.24"x2.2" 4-wire1.8 deg. step angle(200 steps/rev)Rated current 2.8A & resistance 0.9ohms

▼ Read Reddit mentions

▼ Read Reddit mentions34. 58 Pc Pro-Series 5/8" T-Slot Clamping Kit Bridgeport Mill Set Up Set 1/2-13

Our Part # ALL-48010Made of high quality casting steel for long life and increased durability. All parts heat treated.5/8" T-Slot, 1/2-13 stud size, & 1" step block width (all standard)Includes (24) Studs- (4) each of 3", 4", 5", 6", 7", & 8" long </li> <li>Also contains (4) coupling nuts, (6) forge...

▼ Read Reddit mentions

▼ Read Reddit mentions35. CGOLDENWALL Z Axis Zero Pre-setter Tool Setter for CNC Router Mach3 50mm ± 0.005mm Magnetic

For setting length on machine center/lathe centerSetting height :50 +/- 0.005mmLow sprang force, avoids the milling cutter or the drilling bits brokenEasy to be calibrated by a ground parallel or gauge blockBetter paralllelism,sensitivity,and precision for use.

▼ Read Reddit mentions

▼ Read Reddit mentions36. Getting Started with CNC: Personal Digital Fabrication with Shapeoko and Other Computer-Controlled Routers (Make)

▼ Read Reddit mentions

▼ Read Reddit mentions37. Makita LC1230 12" Metal Cutting Saw

- Carbide-tipped blade lasts 50x longer than abrasive wheels; cuts clean, accurate and virtually burr-free

- Quick release vise for secure material retention and fast, repeated cut-offs

- Lock-off button for user convenience

- Quick release support fence adjusts 0-45° for miter cutting

- Shaft lock for easy blade changes with just one wrench

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions38. 6061 Aluminum Rectangular Bar, Unpolished (Mill) Finish, Standard Tolerance, Inch

6061 aluminum provides good corrosion resistance, strength, machinability, and weldabilityUnpolished (mill) surface has no finishStandard tolerance

▼ Read Reddit mentions

▼ Read Reddit mentions39. STEPPERONLINE Nema 23 Stepper Motor 2.83Nm 4A 8-Wire 6.35mm Dual Shaft CNC Mill Lathe Router

- Medium Height/Torque Dual Shaft

- 2.83Nm(400oz.in) holding torque

- NEMA 23 bipolar 2.24"x2.24"x3.3" 8-wire

- 1.8 deg. step angle(200 steps/rev)

- Rated current 4.0A & resistance 0.4ohms

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions40. SainSmart 5 Axis Breakout Board for Stepper Motor Driver CNC Mill

- The maximum matching 5-axis stepper motor driver

- The two-stage signal processing, signal transmission smooth, powerful anti-jamming

- Relay output control interface, can be accessed by the spindle motor or the air pump, water pump, etc

- Five-axis job LED display, visual display products, working condition

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions

Ok, I looked for about an hour and I honestly could not find a video. Here's the best I can do to give you instructions.

(I'll try to skim over the obvious)

First, you're using this edge finder or similar

Offset the edge in the y-direction such that it is towards the part. Bring it in to the part until it touches and keep moving at a lower rate (about .01 should be efficient) until the cylinder looks all but solid. Now moving at about 0.001, keep moving while rubbing your thumb up and down the side inline with the y-axis until you no longer feel a lip. Mark the position and then continue in the same direction by 0.001 (or smaller) until you feel a lip again. At the point that you feel a lip again, you are about .0985 (+- .0005) off from the edge of the part assuming you did this right.

Do the exact same thing on the x-axis.

Let me know how this works out for you. It should be the next best thing to buying a dial edge finder for like $470+

Machining the chocolate directly is going to involve a lot of complexity.

For starters, you'll have to make your whole machine food safe. That means it will need to be sanitizable and your cutting bits will have to not leave any hazardous chemicals or metals behind.

Beyond this, you now face the challenge that chocolate has an extremely low melting point and is therefore likely to melt rather than cut. When I've seen people machine chocolate its typically done in a freezer for this reason.

A simpler solution might be to machine something like jewlers wax into a positive of what you want your chocolate to look like. Then cast the wax in a food-safe silicone.

Once you have that the silicone mold should be able to safely cast the chocolate, and should be reusable to boot.

I would suggest waiting on the ballscrews until you are going to build a bigger machine, a lead screw like this with a diy anti-backlash nut would save a fair bit a money and might work better with your motors. Aluminum and MDF could make a frame solid enough for what you need, I would suggest looking on youtube and seeing what others have done.

If you want to build out of aluminum this and this might be a good place to look for ideas and materials. I haven't bought anything from them myself, but it looks interesting.

What are you planning on using for a motion controller? linux cnc, GRBL?

Where about are you located?

great price, good size for the garage, and since its a gunsmithing you can do something that is really long, there were a lot of reviews on it, and a few people have converted it and seems pretty straight forward conversion.

just picked up a DRO setup for it while planning out the conversion was off amazon, custom cut for the machine and also a decent price for a magnetic DRO setup

https://www.amazon.com/gp/product/B019X9I5I2/ref=oh_aui_detailpage_o08_s00?ie=UTF8&amp;psc=1

That's an interesting concept. I wonder how I'd attach something like this to my rails. This requires more research.

I don't really know much about gears (or rack and pinion). Anyone care to offer advice on pitch, pressure angle, or whatever, for this purpose? It looks at a glance like Amazon has some options, though they're a bit expensive. This might be a future upgrade.

http://www.amazon.com/Boston-Gear-L20206-Degree-Pressure/dp/B004N630GI/ref=sr_1_4?s=industrial&amp;ie=UTF8&amp;qid=1451405391&amp;sr=1-4&amp;keywords=rack+and+pinion

http://www.amazon.com/Martin-14-5%C2%B0-Pressure-Angle-Backing/dp/B0051V9MH0/ref=sr_1_4?s=industrial&amp;ie=UTF8&amp;qid=1451405692&amp;sr=1-4&amp;keywords=rack+and+pinion&amp;refinements=p_n_availability%3A1248818011%2Cp_89%3AMartin

I've been using Venom Steel Nitrile Gloves in my shop and they are good, but not as thick as you'd like. However, Liberty Glove & Safety make some 15 mil nitrile gloves.

I recently read this book with a very different stance on how far this future state is from today:

Humility Is the New Smart: Rethinking Human Excellence in the Smart Machine Age

I'm not saying your wrong, it's fascinating to me that every industry is full of people saying "but my role can't be automated, they will still need a human here".

No you would need a router and a mount. CNCRP sells nice mounts also. The Porter Cable 690 would probably be your best bet and you would still be slightly under your 3k budget.

Porter Cable 690 Mount CNCRP $93

Porter Cable 690 Router - Amazon $125

Those look fine but they aren't super powerful. The g shield can supply 2.5 amps so any motor that needs less power than that will be fine. If you are just cutting wood those steppers are fine, maybe shop around for something with a lower inductance, 13mh is pretty high. These guys look much better but you won't be able to get full current into them:

https://www.amazon.com/dp/B00PNEPF5I/ref=asc_df_B00PNEPF5I5078529/?tag=hyprod-20&amp;creative=395033&amp;creativeASIN=B00PNEPF5I&amp;linkCode=df0&amp;hvadid=198064502357&amp;hvpos=1o1&amp;hvnetw=g&amp;hvrand=4174940156511751979&amp;hvpone=&amp;hvptwo=&amp;hvqmt=&amp;hvdev=m&amp;hvdvcmdl=&amp;hvlocint=&amp;hvlocphy=9032550&amp;hvtargid=pla-323464553412#productDescription_secondary_view_div_1500259475627

Most t-slot clamping kits come with them: https://www.amazon.com/Pro-T-Slot-Clamping-Bridgeport-Mill/dp/B01BH8MTCU

I think they're called "Step Clamps" though: https://www.amazon.com/s?k=step+clamps&amp;i=tools&amp;ref=nb_sb_noss_1

If I'm buying stuff for work though, I usually go through MSCDirect. Don't know if it helps you over there, but they usually send out weekly discount codes in their e-mails. They're better for higher-quality industrial-use stuff, but I don't know if you wanna spend that much! https://www.mscdirect.com/browse/lookahead/?searchterm=step+clamps&amp;hdrsrh=true

Tool change to T0, which should empty the spindle and clear out the active tool offset. Double check to confirm that the tool offset is no longer active.

Jog the spindle down until you can just barely slide a 1-2-3 block (or anything flat and square) between the spindle face and table. You will want to make sure the table and spindle face are nice and clean.

Without moving the spindle, tab over to the Set WO page, and and press the Z=0 softkey. Your current position should now be Z0.

Jog the spindle up in Z, and manually load a tool in the spindle. Bring the spindle down in Z, again until you can just barely slide the 1-2-3 block in between the tool and table.

The position that Z is reading at this point is the gage length of your tool. Tab over to the offset page, and put this length in the Geometry field. Repeat as necessary to measure your tools.

FYI The 1-2-3 block could also be replaced with something like this for greater accuracy. https://www.amazon.com/Pre-setter-Setter-Router-0-005mm-Magnetic/dp/B00O67AKK8/ref=sr_1_1?ie=UTF8&amp;qid=1536510059&amp;sr=8-1&amp;keywords=tool+presetter

The guy who created the Shapeoko line has written a book that is a great into and how to for CNC starters:

https://www.amazon.com/gp/product/1457183366/ref=oh_aui_detailpage_o04_s00?ie=UTF8&amp;psc=1

This thing is tremendous. It looks like a chop saw, but it uses a carbide-tipped sawblade instead of an abrasive disc. Cuts steel in seconds, leaves a clean edge, doesn't heat up the stock like an abrasive saw.

I will second drillman1 on ebay.

I don't have any local suppliers that sell off cuts so I have to resort to online purchase. I've bought a good bit of aluminum off cuts from Metal Remnants Inc on Ebay and have been very happy.

If you have Amazon Prime they actually have what I feel are decent prices on aluminum flat bar and other raw materials.

I'm going to put the links in a comment, I think they caused my post to get removed due to spam filter earlier:

Don't necessarily have to use Amazon, but I'd prefer a US based company.

Thanks!