(Part 2) Reddit mentions: The best electrical motor controls

We found 151 Reddit comments discussing the best electrical motor controls. We ran sentiment analysis on each of these comments to determine how redditors feel about different products. We found 77 products and ranked them based on the amount of positive reactions they received. Here are the products ranked 21-40. You can also go back to the previous section.

21. STEPPERONLINE 1 Axis CNC Kit 3Nm(425oz.in) Nema 23 Stepper Motor & Driver CNC Mill Router Lathe Robot

1 x Digital Stepper Drive 1.0-4.2A 20-50VDC for Nema 17, 23, 24 Stepper Motor1 x Nema 23 Bipolar 3Nm (425oz.in) 4.2A 57x57x114mm 4 Wires CNC Stepper Motor

Specs:

| Weight | 3.968320716 Pounds |

22. ReFaXi Universal Heavy Duty Power Door Lock Actuator Motor 2 Wire w/Hardware 12V New

Fits most of vehiclesEasy to installPowerful and extra durable motorAdd power door lock systems to your carDC 12V

▼ Read Reddit mentions

▼ Read Reddit mentions23. Variable Frequency Drive, CNC 110V 2.2KW 3HP VFD Drive VFD Spindle Inverter Professional Variable Frequency Drive Inverter for Spindle Motor Speed Control (Single phase 110V input, 3HP 110V output)

Variable Frequency Drive Inverter use for: Lathes, Mill, car Hoists, Pumps, conveyors, etc. Notice: the machine can't work on single phase motor, and it can't work with the Mach 3 software.PID control: advanced calculous PID closed-loop arithmetic, quick responding speed and high suitability.RS485 c...

▼ Read Reddit mentions

▼ Read Reddit mentions24. SainSmart 3-Axis GRBL USB Driver Controller Board DIY Engraver Control Board for GRBL

- Applicable Software: GRBL control, Un Gcode Sender, GRBL controller, or other software that supports GRBL code

- Stepper Motor Drivers: A4988 motor driver,16 microstep 1.5A phase current output

- Support Stepper Motor: NEMA17 NEMA23 stepper motor, phase current less than 1.5A

- Spindle Motor Interface: the maximum support 400W DC spindle motor

- With fan interface and TTL signal output interface (for controlling the laser module with TTL module)

Features:

Specs:

| Size | 3-Axis |

25. Router Speed Control

- Dial controls the variable speed (high, medium or low)

- 3-way rocker switch

- 6 ft. cord;

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions26. STEPPERONLINE 50:1 Nema 17 Geared Stepper Motor L=39mm High Precision Planetary Gearbox for 3D Printer DIY CNC

High accuracy, high efficiencyNema 17 stepper motor 39mm length48.3mm Planetary gearbox of 50:1 gear ratioMoment Torque 25Nm(3540oz.in) & Max Torque 15Nm(2124oz.in)Rated current 1.68A & Rated voltage 2.7V

Specs:

| Height | 3.437001 Inches |

| Length | 1.69291 Inches |

| Width | 1.65354 Inches |

27. Yosoo Mini High Torque 6V 50/100/ 150/200/ 300RPM with Metal Gearbox Replacement N20 for RC Car, Robot Model, DIY Engine Toys (6V 150RPM)

- Good performance: This gear motor has great workmanship, perfect replacement for the old one. A great choice for you

- Reliable: The DC gear motor supports guaranteed quality, used with confidence, which is made via many inspections before leaving the factory. You can use it with confidence

- Convenient for use: Professional and practical design with beautiful appearance, easy to carry and use. Bring you a new and different using feeling

- Advantages: The DC gear motor has the advantages of long life, high accuracy, high efficiency, stable performance and easy installation. Its quality is guaranteed

- High quality material: This gear motor made of high quality material, which is sturdy and has long service life. Meet your needs

Features:

Specs:

| Height | 0.787401574 Inches |

| Length | 1.574803148 Inches |

| Size | 6V 150RPM |

| Weight | 0.022 Pounds |

| Width | 0.787401574 Inches |

28. Mini DC Motor PWM Governor 1.8V 3V 6V 9V 12V Speed Switch Uultra-Small LED Dimmer

- System: Intel i7-8750H 2.2GHz Six-Core | Intel HM370 Chipset | 16GB DDR4 | 1TB M.2 SSD | Genuine Windows 10 Home 64-Bit

- Graphics: NVIDIA GeForce GTX 1060 6GB video card | FHD IPS Anti-Glare 15.6" LED Display | Audio: 2.1 Digital Surround Sound Stereo Speakers

- Connectivity: 1x HDMI | 2x Mini DisplayPort | 1x USB 2.0 | 2x USB 3.1 | 1x USB Type C | 1x RJ-45 network Ethernet 10/100/1000 | 802.11 AC Wi-Fi | Bluetooth 5.0 | 2-in-1 Card Reader

- Special feature: Programmable RGB Mechanical Keyboard & Click pad

- 1 Year Limited Warranty & Lifetime Toll Free Tech Support Services

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions29. Leviton MS303-DS 30 Amp 600 Volt, Three-Pole, Three Phase AC Motor Starter, Suitable as Motor Disconnect, Toggle, Industrial Grade, Non-Grounding, Black

- Fits in standard wall box

- Accepts back or side wiring, terminal clamps or ring terminals

- Oversized toggle provides clear actuation feedback and long-lasting durability

- Nickel-plated #10 triple-combination terminal screws for corrosion resistance

Features:

Specs:

| Color | Black |

| Height | 4 Inches |

| Length | 4 Inches |

| Number of items | 1 |

| Weight | 0.34999817097203 Pounds |

| Width | 4 Inches |

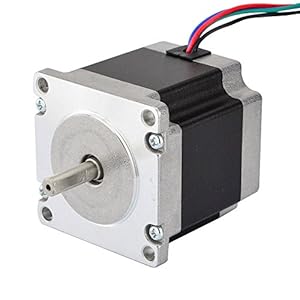

30. STEPPERONLINE Nema 23 CNC Stepper Motor 2.8A 178.5oz.in/1.26Nm CNC Stepping Motor DIY CNC Mill

Higher Torque1.26Nm(178.5oz.in) holding torqueNEMA 23 bipolar 2.24"x2.24"x2.2" 4-wire1.8 deg. step angle(200 steps/rev)Rated current 2.8A & resistance 0.9ohms

Specs:

| Color | As Shown |

| Height | 2.2 Inches |

| Length | 2.24 Inches |

| Size | Small |

| Weight | 1.5 Pounds |

| Width | 2.24 Inches |

31. BEMONOC Reversible 12 Volt Gear Motor 24 RPM with Worm Gearbox for Robot Parts

- ✔Rated voltage: DC12V; No-load speed: 24 Rpm; Rated torque: 4.2kg.cm; Rated Current: 0.31A;

- ✔Reduction ratio: 1/330; Protection class: IP54; Low noise: db<45 (A); Certification: CE; Material: Metal; Commutation: Brush;

- ✔Gear Motor Body Dimensions: 3 x 1.25 x 1.06inches(L*W*H); Out Shaft Dimensions: 0.53*0.23inches(L*D) with 0.047*0.43inches flat cut off;

- ✔Usage: Windows and Doors, Car, Boat and Robot model, Industry application, house application, home automation ,mini winch and other occasions;

- ✔Package: 1PCS x DC Geared Motor; if you need other voltage and rpm, pls contact us, there are many other models of this motor in store.

Features:

Specs:

| Color | 12V |

| Size | 24RPM |

32. 5HP 1-Phase 230V Definite Purpose Motor Starter for Electric Motor from SQUARE D, Model 8911DPSG32V09, 8911DPSO32V09

- NEW MAGNETIC MOTOR STARTER FOR 5HP 230V ELECTRIC MOTORS, SINGLE PHASE

- 30 AMP CONTACTOR, INCLUDES NEMA 1 GENERAL PURPOSE ENCLOSURE, 1 THERMAL OVERLOAD / HEATER ELEMENT INCLUDED

- SQUARE D MODEL NUMBER 8911DPSG32V09, 8911DPSO32V09

- PROFESSIONAL INSTALLATION REQUIRED

Features:

Specs:

| Height | 13 Inches |

| Length | 0 Inches |

| Weight | 10 Pounds |

| Width | 9 Inches |

33. HobbyUnlimited Nema 34 Stepper Motor 6A 8.5Nm (1200 oz-in) 118mm Length for CNC Router Mill Lathe, Black

- Nema 34 118mm length stepper motor.

- 8.5Nm (1204 oz-in) torque.

- Weight: 3.6kg

Features:

Specs:

| Color | Black |

| Weight | 7.936641432 Pounds |

34. STEPPERONLINE 1 Axis Stepper CNC Kit 8.5Ncm(1204oz.in) Nema 34 Stepper Motor & Driver

- 1 x Digital Stepper Drive 2.4-7.2A 18-80VAC or 36-110VDC for Nema 34 Motor

- 1 x Dual Shaft Nema 34 CNC Stepper Motor 8.5Nm (1204oz.in) 5A 86x114mm

Features:

▼ Read Reddit mentions

▼ Read Reddit mentions35. SainSmart 5 Axis Breakout Board for Stepper Motor Driver CNC Mill

- The maximum matching 5-axis stepper motor driver

- The two-stage signal processing, signal transmission smooth, powerful anti-jamming

- Relay output control interface, can be accessed by the spindle motor or the air pump, water pump, etc

- Five-axis job LED display, visual display products, working condition

Features:

Specs:

| Number of items | 1 |

36. A4988 Stepper Motor Driver

Simple step and direction control interfaceFive different step resolutions: full-step, half-step, quarter-step, eighth-step, and sixteenth-stepAdjustable current control lets you set the maximum current output with a potentiometer, which lets you use voltages above your stepper motor’s rated volta...

Specs:

| Weight | 0.02 Pounds |

37. CNC 7.5kw 7500w 220v 10HP 34a 10hp Variable Frequency Drive Inverter VFD for Spindle Motor Speed Control

- Easy PLC function can realize 16 legs of speed and inverter control function

- RS485 communication port, adopting standard international MODBUS main circuit control

- Carrier adjustable by 16KHZ, completely soundless working environment

- Various control technique by both synchronization and non-synchronization

- Auto voltage regulation (AVR) technique, for ensuring the inverter load capability

Features:

Specs:

| Color | Black |

| Height | 6.692913379 Inches |

| Length | 8.661417314 Inches |

| Weight | 6.61386786 Pounds |

| Width | 5.905511805 Inches |

38. CCM5D speed controller LED digital display PWM DC motor speed controller 6V12V24V30V stepless speed control switch controller

- CCM5D 6V-30V 6A 16kHz speed controller LED digital display Applicable to DC6V - 30V DC motor, fan, fish tank oxygen pump and other products.

- Maximum 30V * 8A = 240W Input voltage: DC6V - 30V Control power: 0.01W - 240W Applicable current: rated current 5A, maximum passing current 8A, PWM pulse width Speed range: 0% - 100% PWM frequency: 16khZ

- The DC motor speed controller allows the use of pulse width modulation (PWM) DC voltage to control the speed of the DC motor, and the duty cycle can be fully adjusted from 0% to 100%.

- Easily deliver 5A continuous current to your DC motor or other DC load. Input power supply voltage: 6V-30VDC motor speed controller,

- Let you be satisfied with our services, not just our products. If you are not satisfied with our products for any reason, simply contact the support department for a replacement or refund. We will answer any questions you may have within 24 hours.

Features:

Specs:

| Height | 0.5118110231 Inches |

| Length | 3.1102362173 Inches |

| Weight | 57 Grams |

| Width | 1.6535433054 Inches |

39. NOYITO Optocoupler isolation MOS FET 10A DC 2.7-27V High-Power Field Effect Tube Driver Module 0-20Khz PWM Switch Control Board Development Board Module

Input signal: PWM signal between 3-20V.<br>Output capacity: DC 3.7V-27V, 10A Max.<br>PWM frequency: 0~20Khz.<br>Application: Can input PWM, control motor speed, lamp brightness and so on.<br>Please read the second picture on the left for the product wiring diagram or download the user manual.User Ma...

▼ Read Reddit mentions

▼ Read Reddit mentions🎓 Reddit experts on electrical motor controls

The comments and opinions expressed on this page are written exclusively by redditors. To provide you with the most relevant data, we sourced opinions from the most knowledgeable Reddit users based the total number of upvotes and downvotes received across comments on subreddits where electrical motor controls are discussed. For your reference and for the sake of transparency, here are the specialists whose opinions mattered the most in our ranking.

You're going to get flex the first time you try to mill anything significant when Y is pulling on X, the fact it feels solid to you when you pull on it with your hands is immaterial.

A CNC mill needs a solid aluminum extrusion frame or better, full stop. Especially if you want to "take a quarter inch out of copper"

You're getting into the territory of non-trivial machining, and hobby grade equipment isn't up to the task, and the difference is reflected in price.

Also, yes the steppers are grossly insufficient, you're going to need to get a pair of something like this for the axis steppers, driving solid threaded rods or ballscrews. 3d printer sized nema steppers and belts will not provide the torque required, and the steppers we use will not put out the power needed to step the big boys under load. You'll need a more powerful PSU too, these larger stepper motors can draw at peak as much as all the steppers on a Prusa style machine combined.

https://www.amazon.com/dp/B012QFRKAO/ref=cm_sw_r_cp_apa_qaqUBbYKSTW5H

A latch solenoid should only be activated to unlock, and then only for a short time, lest it overheat. These should be fine for batteries. However, solenoids are generally pretty weak; any pressure, whether from spring or human pulling or warped hinge or anything will tend to bind them up. Car door locks are better. A linear actuator is very strong and reliable, but usually aren't short enough to be a latch.

You may be interested in a cabinet latch. This type has a nice "pop" open.

You can't use a speed control like the one you have linked. Those are for universal/brushed AC motors only; using one with a induction/capacitor motor like you have is bad for the windings. You need a VFD.

The advantage of using a VFD and induction motor is that you get full torque unlike what you would get using the AC chopping speed control like you purchased when used with a universal motor. Your only other option would be to use a DC motor, but then that gets very expensive pretty quickly.

If you do buy the VFD you should also get a 10K potentiometer to go with it; something with a big knob so it's easily adjustable and so you don't have to get clay all over your nice new VFD.

I would say that if you're going to upgrade the rods and such and have access to a 3D printer (which you will need to do that), just buy your own extrusions and build it yourself. Use a dual rail gantry to hold up the beefier 12mm rods to stiffen everything then get a 500w or so spindle and driver from Amazon. The default 3018 spindle is weaksauce. No sense buying any of it, you'd just be replacing it all. All the parts are available on Amazon, and better 3018 parts are available on Thingiverse.

Get a raspberry Pi and a Protoneer CNC Hat (my current solution for the 3018) or just get a cheap GRBL controller from Amazon. That way you can get the nice Trinamic drivers and such too if you want it to be quieter.

They are commonly used for fan speed or router speed controllers and for $20 well worth the cost. Harbor freight carries them or there a ton on Amazon like this one. I just zip tied the trigger on the drill all the way on then dial the knob up until I’m at the manufacturers recommended rpm (200 for my monster mill).

Buy a swagelok valve from here (paying full price is for suckers and these guys ship faster than Swagelok anyways). For reference you can get a brand new swagelok for less than $40 from this site. Just compare the part number to the swagelok website to check seal/o ring materials.

Buy a high torque stepper motor and hook it up to the valve. You will also need a stepper motor driver that can deliver sufficient amperage. This is pretty much the simplest/cheapest way to get 150 in-lbs of torque delivered to the valve. Theoretically you'd only need about 50 but better safe than sorry.

This is the cheapest and simplest way to get what you want. If you already have gear for pneumatic control (air tank, solenoids, regulator, etc) pneumatic might be cheaper but you also don't get fine position control with pneumatic so take that as you will.

How did you fit the drive sprockets, and what circuits did you use?

You mentioned off the shelf stuff, so I'm mildly curious.

And by gearbox, I assume you mean something like this?

https://www.amazon.com/Yosoo-Torque-300RPM-Gearbox-Replacement/dp/B01NCQTK3S/ref=sr_1_2?ie=UTF8&amp;qid=1519191975&amp;sr=8-2&amp;keywords=200+rpm+metal+gear+motor

I would go back to the drawing boards and first understand how rgb led’s work and then look into pulse with modulation (PWM). I would agree with everyone else that voltage regulating isn’t what you need.

I’m assuming that your strips are rated for 12V and since they will be connected to 12V they are good in terms of voltage. Now in order to tune to specific colors you’ll need a PWM setup. You could use the pots you have in order to achieve what you want, but the LM317 or LM337 is not the correct route for this. If you want a simpler A>B setup that has dialed controls something like this would be what you would want.

Mini DC Motor PWM Governor 1.8V 3V 6V 9V 12V Speed Switch Uultra-small LED Dimmer https://www.amazon.com/dp/B01MXR4TSD/ref=cm_sw_r_cp_api_i_qxYnDb7TCVTHG

That sounds like a cool project, can I ask what features are being added with IOT integration? I assume the loadbank is for testing the generators?

Here's a pretty good motor control video that explains the basics. If you post a picture of the diagram I can probably help you with the connection, it might even already be correct.

I'm used to magnetic motor starters so that's what I suggested but for such a small motor you can probably get away with a horsepower rated 3 pole switch like this and skip the overloads.

Those look fine but they aren't super powerful. The g shield can supply 2.5 amps so any motor that needs less power than that will be fine. If you are just cutting wood those steppers are fine, maybe shop around for something with a lower inductance, 13mh is pretty high. These guys look much better but you won't be able to get full current into them:

https://www.amazon.com/dp/B00PNEPF5I/ref=asc_df_B00PNEPF5I5078529/?tag=hyprod-20&amp;creative=395033&amp;creativeASIN=B00PNEPF5I&amp;linkCode=df0&amp;hvadid=198064502357&amp;hvpos=1o1&amp;hvnetw=g&amp;hvrand=4174940156511751979&amp;hvpone=&amp;hvptwo=&amp;hvqmt=&amp;hvdev=m&amp;hvdvcmdl=&amp;hvlocint=&amp;hvlocphy=9032550&amp;hvtargid=pla-323464553412#productDescription_secondary_view_div_1500259475627

Get a worm drive motor like this and at the point where the blinds are at the very bottom and the string is at the top tie a knot and attach one single string that goes down to the motor and also attach some little collars on the string permanently and add a 2:1 pulley advantage so when the motor pulls 1 foot then the rope for the blinds moves 2 feet and the collars will attach to limit switches so you don't break anything and you will be fine

BEMONOC Reversible 12 Volt Gear Motor 24 RPM with Worm Gearbox for Robot Parts https://www.amazon.com/dp/B01D2GQSLS/ref=cm_sw_r_cp_apa_i_TyDSDb0QHVKSC

Compressors are already automated, they turn on and off based on pressure. If you want to control them further you need a contactor that can handle the current and the voltage. Your average smart plug typically can't handle the switching the current directly. You can use a smart plug to turn the power to the contactor's coil on and off.

Another option would be a normally closed valve on the compressors output. It might be cheaper than the contactor.

In most cases you will also require the services of an electrician to properly install the contactor.

Something like this:

https://www.amazon.com/1-Phase-Definite-Electric-8911DPSG32V09-8911DPSO32V09/dp/B07DFNR5FH/

This is probably your best shot, my guy:

https://www.amazon.com/Stepper-Motor-8-5Nm-Length-Router/dp/B077X9R2CW/

Amazon says it'll ship by Monday. You could even mail it back on Wednesday and probably get your money back if it's undamaged.

Does anybody have any recommendations on an acceptable quality 10 hp vfd that costs less than $450?

Is this one any good? https://www.amazon.com/Variable-Frequency-Inverter-Spindle-Control/dp/B010CJBVOC/ref=sr_1_1?ie=UTF8&amp;qid=1511929845&amp;sr=8-1&amp;keywords=10+hp+vfd

I'm going to put the links in a comment, I think they caused my post to get removed due to spam filter earlier:

Don't necessarily have to use Amazon, but I'd prefer a US based company.

Thanks!

I'd buy a bunch of 3D printer stepper motor drivers like this one, and use breadboard or prototyping board to wire them up to the Arduino board.

https://www.amazon.com/Pololu-A4988-Stepper-Motor-Driver/dp/B007MX9LVW

Not much involved in driving them. You have to set the MSx pins on the driver to set the microstepping ratio you want, then each of them accept a step/direction input which steps the motor one way or the other.

Just to chime in on these they are amazing and at ~$20 I don't mind having a spare or two.

If you want to get fancy you add one of these and you can control the speed of the pump too.

A PWM controlled fan is the first thing that came to my mind. Looks like some have done it before. https://community.home-assistant.io/t/pwm-controlled-fan-with-esphome-on-esp32/134113. Using https://www.amazon.com/dp/B07R4VCCPL + d1 mini perhaps?

https://www.amazon.com/Makermotor-Reversible-Electric-Gear-Motor/dp/B00LTM3AT6/ref=sr_1_20?ie=UTF8&amp;qid=1503169148&amp;sr=8-20-spons&amp;keywords=small+electric+motor&amp;psc=1

Something like this might work. If you look down at "Frequently bought together" there's a a speed controller. If you affixed a rod to the motor driver, and then affixed it to a pully wire it might work. You may need a more powerful motor though. It would definitely take a bit of engineering, but it should be doable.

Motor: https://www.amazon.com/HobbyUnlimited-Stepper-Motor-Length-Router/dp/B077X9R2CW

Driver: https://www.digikey.com/product-detail/en/TMC5160-BOB/1460-1250-ND/8440397

Oh boy time to buy a mill and convert it to a <$1.5k CNC mill to make small parts!

Motor speed controller